Execution commences for the Pengerang Energy Complex in Johor, Malaysia

-

Based on UOP’s recent technical innovations, the PEC is likely to have a 30% lower carbon footprint than UOP’s similarly installed plants

-

Major O&M contract awarded to Zeit Operation & Maintenance Co., Ltd for operations and maintenance services for the PEC

SINGAPORE, 28 February 2024 – Singapore-based petrochemicals, green energy and natural resources conglomerate, ChemOne Group, master developer of the Pengerang Energy Complex (“PEC”) has confirmed the commencement of execution for the PEC with engineering progressing well for the aromatics project in Johor, Malaysia.

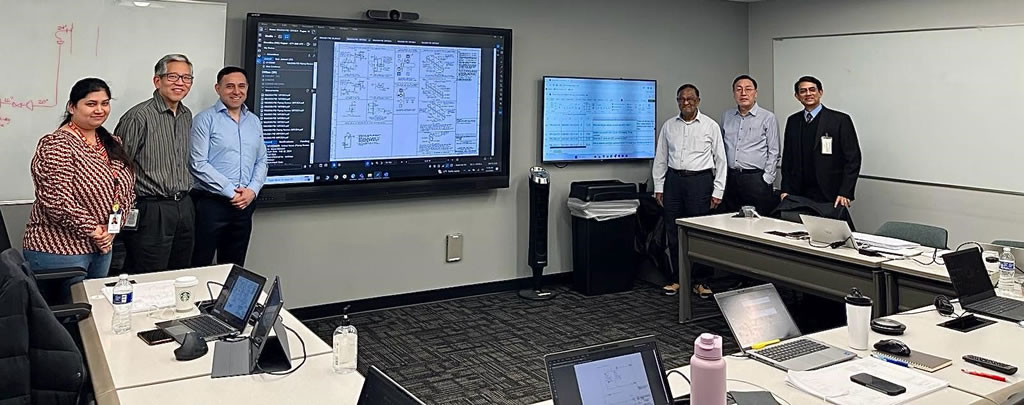

Customer Review meetings for key documentation have taken place since the start of the year with the project’s technology provider and EPCC contractor, Honeywell UOP, at its HQ in Des Plaines (Chicago), USA. The ultimate goal of these meetings has been to secure maximum plant efficiency, lowest energy requirements, and lowest carbon footprint.

Key agenda items discussed at these meetings include the adoption of new Honeywell UOP technologies to meet the project’s low carbon aspirations, and construction planning reviews focused on achieving fastest time to Project Start-Up, currently targeted for the end of 2027. Based on UOP’s recent technical innovations, the PEC is likely to have a 30% lower carbon footprint than UOP’s similarly installed plants.

Mr. Alwyn Bowden, CEO of Pengerang Energy Complex Sdn Bhd, said: “We are delighted to announce the commencement of execution for the PEC. Crucial meetings with our partners has seen us continue to beat industry standards when it comes to the project’s carbon intensity. We look forward to conquering further benchmarks as we finalise our lineup of top-tier contractors.”

Operations and Maintenance Services Contract Award

The PEC has awarded Zeit Operation & Maintenance Co., Ltd., (“Zeit”) a wholly owned subsidiary of leading Korean conglomerate GS Engineering & Construction Corporation, the operations and maintenance contract for the project.

The scope for Zeit during the Planning as well as Engineering, Procurement and Construction (EPC) phases entails assistance related to operational and training plans for PEC employees across disciplines, development of plant maintenance philosophies and recommended state-of-the-art tools to enhance operational efficiency. During the Operations phase, Zeit will supervise and analyse the operations, monitor and advise on start-up and troubleshooting, as well as perform process optimisation.

Mr Park Seung-Bum, CEO of Zeit Operation & Maintenance Co., Ltd., said: “We are delighted to collaborate with PEC and contribute to the establishment of one of the largest low-carbon aromatics production and refining facilities in the region. We eagerly anticipate the successful completion of the project.”

GS Engineering & Construction (GS E&C), the parent company of Zeit, has more than 40 years of proven track record in providing integrated EPC services, having gained extensive O&M experience working with international refining and petrochemical groups who hold world ranking status in every field of operations and maintenance excellence.

– End –

For media enquiries, please contact Klareco Communications, on behalf of ChemOne Group

Name: Ruby Tyler / Caitlin Gomez

Email: Klareco-ChemOne@klarecocomms.com

Number: +65 9423 4810

About Pengerang Energy Complex

Pengerang Energy Complex (“PEC”) is set to be one of the largest and most competitive integrated condensate splitter and aromatics facilities in the world. PEC is located in the Pengerang Integrated Petroleum Complex (PIPC) in Johor, at the southern-most tip of Peninsular Malaysia and directly opposite the City State of Singapore, sharing its attributes as a central trading hub and deep-water port.

PEC’s strategic location at the crossroads between buyers or product demand centres in the Asian markets and feedstock suppliers in the USA, Middle East and Australia, makes it an ideal hub for the petroleum and petrochemical industries. The resulting downstream products are used in a wide range of consumer products (textiles, bottles, housing, pharmaceuticals).

The 6.5 million metric tonnes per annum (mmtpa), facility is capable of processing 150,000 barrels per day (bpd) of condensate plus side feed of naphtha, that will in turn produce aromatics of 2.3 mmtpa, energy products output of 3.9 mmtpa and hydrogen output of 50,000 metric tonnes per annum (mtpa).The condensate splitter will produce heavy naphtha, a primary feedstock for the aromatics plant whereas the hydrogen produced is planned to be used to support development of downstream renewable fuels facilities in Johor.

The US$5 billion project is estimated to generate an annual export turnover of US$5 billion for Malaysia. Involving fully automated processes, the greenfield PEC has been designed to optimize energy efficiency, minimize equipment size, and significantly reduce greenhouse gas emissions in line with International Financial Corporation’s (IFC) performance standards.

Offering the latest technological advances, the world-class PEC facility will be one of the largest and most energy efficient integrated condensate splitter and aromatics facilities globally, strategically located to serve the regional Asian markets and satisfy forecast long-term sustained regional growth.

ChemOne Group, a leading energy and petrochemicals project developer based in Singapore, is the master developer for the project. ChemOne’s successful track record over the last 40 years includes managing the end-to-end, award-winning project financing for the Jurong Aromatics Complex in Singapore.